Uniservice Unisafe stands as an authorized dealer and service station for a comprehensive range of essential equipment, including Portable and Fixed Gas Detectors, Ullage-Temperature-Interface (UTI), Tube Measurement System, Manometers, Thermometers, Alcohol Testers, Regulators, and Flowmeters from top-tier brands. Our commitment extends beyond supply, as Uniservice Unisafe offers meticulous technical calibration with an emphasis on swift turnaround times. Armed with the appropriate tools and expertise, our team conducts thorough inspections and precise calibrations for all detectors. As part of our dedication to compliance and safety, each calibrated detector is returned with a new compliance certificate, assuring peak performance and adherence to regulations.

Gas Detectors Tubes UTI Calibration Gas Mixtures Fixed Gas Detectors Thermometers Alcohol Testers Regulators Flowmeters

Authorized Dealer and Service Station

Gas Detectors

Span Gases & Regulators

Termometers & Pressure Calibrators

UTI - Ullage Temperature Interface

Tubes Gas Detectors

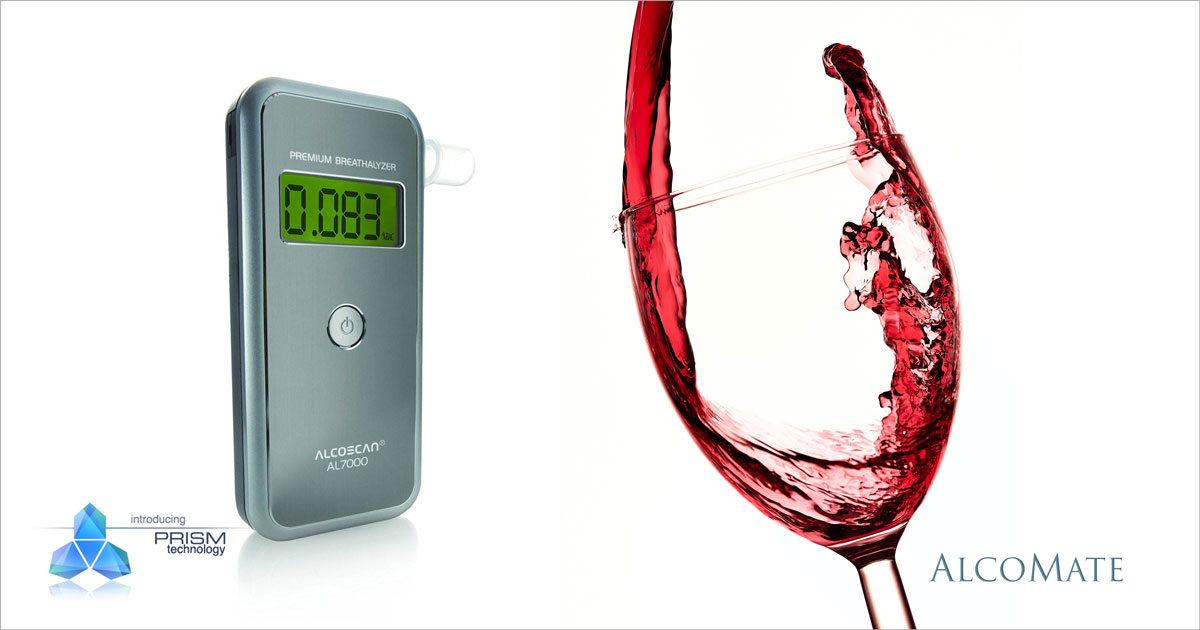

Breath Testing

What are these?

We offer a wide range of gas mixtures tailored for calibrating Marine gas detection systems, with applications spanning Inert Gas Systems, protection of Water Ballast Tanks / Pump Rooms, Accommodation Rooms, and Scrubber Systems. (read below)

Span Gases: When it comes to ensuring accurate gas detection, Uniservice Unisafe offers a specialized range of span gas cylinders, also known as calibration gases. These meticulously formulated mixtures are tailored specifically for the maritime industry. We understand the critical importance of periodic calibration for gas detectors to maintain their accuracy and reliability. Calibration involves exposing the gas detector to known concentrations of gases, validating that its readings align with actual gas concentrations. Our span gases are meticulously designed to contain precise concentrations of target gases, closely aligned with the instrument's measuring range. This alignment ensures that by calibrating with our span gases, the detector's sensitivity and accuracy can be fine-tuned, ultimately resulting in accurate readings during real-world usage.

Our range of span gas cylinders comprises mixtures of both reactive and non-reactive gases, and these cylinders come in various sizes to accommodate different needs. Some of the most common cylinder sizes include:

✓ 2AL: 34 liters, pressure at 35.5 bar

✓ 10ALU: 116 liters, pressure at 69 bar

✓ 5AL: 750 liters, pressure at 150 bar

✓ 10AL: 1500 liters, pressure at 69 bar

✓ 10ST: 1500 liters, pressure at 150 bar

These cylinder sizes cater to different calibration requirements, ensuring that you have the right amount of span gas for your specific applications.

Regulators are devices used to control the flow of gases from a pressurized gas cylinder to the instrument being calibrated. In the context of gas detectors, regulators are used to ensure that a consistent flow of span gas is delivered to the detector during the calibration process. This helps maintain a stable and controlled environment for calibration. Regulators typically have pressure gauges and controls to adjust the flow rate of gas to match the requirements of the calibration procedure.

Here at Uniservice Unisafe, our span gas solutions and regulators work together to elevate safety and security in maritime operations. We take pride in delivering superior products that are tailored to address the unique challenges of the maritime industry. By setting high standards for gas detector performance at sea, we aim to be your trusted partner, providing top-notch gas detection and calibration solutions that prioritize quality and precision.

Read more about Gas Mixtures Components

Portable gas detectors play a vital role in ensuring safety and preventing potential hazards in the maritime industry. These devices are designed to be carried by individuals, enabling them to quickly identify and respond to the presence of hazardous gases in various maritime settings. Here's how portable gas detectors are applied in the maritime sector: (read below)

- Emergency Response: In emergency situations such as fires, gas leaks, or accidents, portable gas detectors provide real-time information about the presence of gases, allowing emergency response teams to make informed decisions and take appropriate actions to mitigate risks and protect personnel.

- Drilling Rigs and Offshore Platforms: In offshore drilling and exploration activities, portable gas detectors are used to monitor gas levels on drilling rigs and offshore platforms. They help prevent gas-related accidents and ensure the safety of workers in remote and potentially hazardous environments.

- Marine Surveys and Inspections: Portable gas detectors are also used by marine surveyors and inspectors to assess the condition of vessels, ensuring compliance with safety regulations and identifying any potential gas-related issues that need attention.

- Shipyard Operations: During ship maintenance, construction, and repair operations, portable gas detectors are crucial for detecting gases released from welding, painting, and other processes that can pose health and safety risks to workers.

Overall, portable gas detectors in the maritime industry, including those offered by Uniservice Unisafe, play a crucial role in identifying and mitigating gas-related hazards, enhancing safety protocols, and ensuring the well-being of crew members and the environment. Their ability to provide real-time gas concentration readings empowers maritime professionals, facilitated by Uniservice Unisafe's expertise, to make informed decisions and take prompt actions to prevent accidents and protect lives.

Fixed gas detector systems are integral to maritime safety, providing continuous monitoring and early detection of hazardous gases in various settings on ships, vessels, and offshore installations. Here's how fixed gas detector systems are applied in the maritime industry: (read below)

- LNG and LPG Carriers: Vessels carrying liquefied natural gas (LNG) or liquefied petroleum gas (LPG) require specialized gas detection systems to monitor for leaks and prevent the buildup of explosive or flammable gases. Fixed detectors in these cases play a pivotal role in preventing accidents.

- Ballast Tanks and Bilge Areas: Gas detectors are employed in ballast tanks and bilge areas to monitor for gases that can accumulate due to water ingress or cargo residues. Detecting gas buildup helps prevent corrosion, structural damage, and potential explosions.

- Offshore Platforms and Drilling Rigs: Fixed gas detection systems are crucial for offshore installations, such as oil platforms and drilling rigs. These systems monitor for a wide range of gases, including hydrocarbons and toxic gases, to ensure the safety of workers and prevent environmental incidents.

- Pier Operations: In ports and pier areas, fixed gas detectors are used to monitor cargo loading, unloading, and storage operations for any gas leaks that could pose risks to workers, vessels, or nearby communities.

- Safety Compliance: Fixed gas detectors are essential for meeting safety regulations and standards set by maritime authorities and international organizations. Regular monitoring and prompt response to gas alarms are essential components of maritime safety protocols.

In summary, fixed gas detector systems, including those provided by Uniservice Unisafe, are critical components of maritime safety infrastructure. They offer continuous monitoring and early warning of hazardous gas concentrations in various areas of ships, vessels, and offshore installations. These systems, actively implemented by Uniservice Unisafe, effectively help prevent accidents, protect crew members, maintain vessel integrity, and ensure compliance with safety regulations. As an active player in maritime safety, Uniservice Unisafe's contributions significantly contribute to the overall safety and efficiency of maritime operations.

In the maritime industry, both temperature and pressure calibrators are essential tools for maintaining safety, efficiency, and compliance. Regular calibration activities, often performed by trained technicians or specialized service providers such as Uniservice Unisafe, help prevent accidents, ensure reliable performance of critical systems, and contribute to the overall success of maritime operations. (read below)

Temperature and pressure calibrators play a significant role in the maritime industry, ensuring the accuracy and reliability of instruments and systems used onboard ships and marine facilities. Here's a closer look at temperature and pressure calibration in the maritime sector:

1. Temperature Calibrators:

Purpose: Temperature calibrators are used to verify and adjust temperature measurement instruments on ships, such as thermocouples, resistance temperature detectors (RTDs), and temperature transmitters. Accurate temperature readings are critical for various applications, including engine monitoring, cargo storage, and environmental control systems.

Types: There are different types of temperature calibrators, including dry-well calibrators, liquid bath calibrators, and infrared temperature calibrators. Each type serves specific calibration needs.

Maritime Applications: Temperature calibrators are used to ensure the accuracy of temperature sensors in engine rooms, refrigeration systems, and cargo holds. Properly calibrated instruments help prevent equipment malfunctions, maintain optimal storage conditions for perishable goods, and ensure the safety of crew and passengers.

Regulatory Compliance: Compliance with maritime regulations, such as the International Maritime Organization's (IMO) SOLAS (Safety of Life at Sea) requirements, often mandates the regular calibration of critical temperature instruments on vessels.

2. Pressure Calibrators:

Purpose: Pressure calibrators are used to verify and adjust pressure measurement devices like pressure gauges, transmitters, and relief valves. Maintaining accurate pressure readings is essential for the safe operation of various systems on board ships, including hydraulic systems, ballast tanks, and fuel storage.

Types: Pressure calibrators come in various forms, such as hand-held digital calibrators, deadweight testers, and hydraulic pressure calibrators. The choice depends on the specific calibration requirements.

Maritime Applications: Pressure calibration is vital for ensuring the integrity of pressure vessels, pipelines, and safety relief systems. Accurate pressure measurements help prevent overpressure situations, leaks, and other potentially hazardous incidents.

Safety: Pressure calibrators help in identifying and addressing pressure-related issues before they can lead to equipment failures or safety hazards. Regular calibration contributes to the overall safety of maritime operations.

Compliance: Compliance with maritime regulations, such as those outlined in classification societies' rules (e.g., Lloyd's Register, DNV GL), often requires the calibration of pressure instruments to ensure vessel safety and seaworthiness.

Uniservice Unisafe, as a dedicated supplier, offers a comprehensive range of calibration solutions. We provide Calibration Kits and Calibration Services tailored to the specific needs of the maritime sector. Our commitment to excellence ensures that our calibration services meet the stringent standards of the industry.

The results of our calibration services, performed by our expert technicians, are meticulously documented to ensure compliance with regulatory and quality assurance requirements. With Uniservice Unisafe, you can trust in the accuracy and reliability of your maritime instrumentation.

Ullage Temperature Interface Detectors (UTI) are essential components used in the maritime industry for precise measurements and monitoring of liquid cargo levels and temperatures within storage tanks on ships and marine vessels. These detectors play a crucial role in ensuring the safe and efficient transport and storage of various liquids, such as crude oil, chemicals, and other bulk cargoes. (read below)

Uniservice Unisafe, as an active supplier in the maritime industry, provides Ullage Temperature Interface Detectors (UTI) along with a range of other maritime-related solutions. We understand the critical importance of accurate cargo monitoring and safety in maritime operations.

UTIs are typically equipped with advanced sensors and technology that enable them to perform the following functions:

1. Ullage Measurement: UTIs accurately measure the empty space (ullage) within a storage tank. This information is vital for determining the quantity of liquid cargo present and ensuring that tanks are neither overfilled nor underfilled, which could result in safety hazards or economic losses.

2. Temperature Measurement: UTIs also monitor the temperature of the liquid cargo. Accurate temperature data is essential for cargo custody transfer calculations, especially for cargoes whose volume varies significantly with temperature changes.

3. Interface Detection: UTIs can detect the interface between different liquid layers within a tank, which is crucial when transporting multiple cargoes in the same tank. They ensure the separation of different substances, preventing contamination.

4. Data Recording: Modern UTIs are often equipped with data logging capabilities, allowing for the continuous recording of ullage and temperature data. This recorded information can be used for compliance reporting, cargo quality control, and safety assessments.

5. Safety and Compliance: UTIs contribute to the overall safety of maritime operations by helping to prevent overflows, ensuring cargo integrity, and facilitating compliance with international regulations and standards.

Uniservice Unisafe offers a range of essential solutions for the maritime industry, with a particular focus on UTI (Ullage Temperature Interface Detectors). Our comprehensive maritime services include:

UTI Supply: We provide high-quality UTIs designed to meet the rigorous demands of the maritime sector. These detectors are engineered for reliable, precise, and industry-compliant measurements, ensuring the safe and efficient handling of liquid cargo on ships and marine vessels.

Calibration Services: Our expert technicians provide calibration services specifically tailored to UTIs, maintaining their accuracy and reliability. The results of our calibration services are meticulously documented to adhere to regulatory and quality assurance requirements, enhancing the precision of your UTI measurements.

Repair Services: In the event of UTI malfunction or damage, Uniservice Unisafe offers expert repair services to quickly restore your equipment to optimal working condition. Our dedicated technicians are well-versed in UTI repair, minimizing downtime and ensuring your cargo operations remain efficient.

With Uniservice Unisafe, you can trust in the quality of our UTIs and the expertise of our calibration and repair services. We are committed to providing comprehensive UTI solutions and other maritime services that enhance safety, efficiency, and compliance in maritime operations.

Breath testing in the maritime industry is a crucial safety measure designed to ensure that ship crew members, especially those in safety-sensitive roles like navigating officers, engineers, and operators of heavy machinery, are fit for duty and not under the influence of alcohol or other impairing substances. (read below)

This testing is essential for maintaining the safety of maritime operations, protecting lives, and preventing accidents at sea.

Uniservice Unisafe, a trusted supplier in the maritime industry, provides high-quality breathalyzer devices designed specifically for maritime use. These breathalyzers are essential tools in ensuring compliance with alcohol-related regulations and maintaining safety on board vessels.

Here's an elaboration on breath testing in the maritime industry:

1. Safety and Operational Impact:

- Safety is paramount in the maritime industry. Impaired individuals can pose significant risks to the safety of the crew, the vessel, and the environment.

- Breath testing helps identify individuals who may be unfit for duty due to alcohol consumption or substance use, reducing the potential for accidents, collisions, or operational errors.

2. Regulatory Compliance:

- Many maritime authorities and organizations, such as the International Maritime Organization (IMO), require compliance with strict regulations regarding alcohol and substance use among seafarers.

- Breath testing helps maritime companies and vessels meet these regulatory requirements and maintain their legal and operational standing.

3. Testing Procedures:

- Breath testing typically involves the use of breathalyzer devices that analyze a person's breath to measure blood alcohol concentration (BAC) levels.

- Crew members may be subject to random testing, pre-employment testing, post-incident testing, or testing based on reasonable suspicion.

4. Zero Tolerance Policies:

- Some maritime companies implement zero tolerance policies, meaning any detectable level of alcohol or illegal substances in a crew member's system can result in disciplinary action or dismissal.

- These policies send a strong message about the importance of sobriety and safety within the maritime industry.

5. Education and Awareness:

- Maritime companies often provide education and awareness programs to inform crew members about the risks associated with alcohol and drug use while on duty.

- These programs aim to promote responsible behavior and emphasize the importance of adhering to safety protocols.

6. Random Testing:

- Random breath testing can deter crew members from consuming alcohol or drugs during their off-duty time, as they never know when they may be selected for testing.

- It helps maintain a culture of sobriety and responsibility.

7. Positive Impact on Safety Culture:

- Breath testing can contribute to fostering a safety-conscious culture among maritime professionals, where sobriety and safety go hand in hand.

- It reinforces the idea that everyone on board plays a critical role in ensuring the safety of the vessel and its crew.

In summary, breath testing is a vital component of safety measures in the maritime industry, and Uniservice Unisafe, as a trusted supplier of breathalyzers, plays a crucial role in providing the necessary tools for compliance and safety. It helps ensure that crew members are fit for duty and not impaired by alcohol or substances, contributing to the overall safety and responsibility within the maritime sector.

What are these?

We offer a wide range of gas mixtures tailored for calibrating Marine gas detection systems, with applications spanning Inert Gas Systems, protection of Water Ballast Tanks / Pump Rooms, Accommodation Rooms, and Scrubber Systems. (read below)

Span Gases: When it comes to ensuring accurate gas detection, Uniservice Unisafe offers a specialized range of span gas cylinders, also known as calibration gases. These meticulously formulated mixtures are tailored specifically for the maritime industry. We understand the critical importance of periodic calibration for gas detectors to maintain their accuracy and reliability. Calibration involves exposing the gas detector to known concentrations of gases, validating that its readings align with actual gas concentrations. Our span gases are meticulously designed to contain precise concentrations of target gases, closely aligned with the instrument's measuring range. This alignment ensures that by calibrating with our span gases, the detector's sensitivity and accuracy can be fine-tuned, ultimately resulting in accurate readings during real-world usage.

Our range of span gas cylinders comprises mixtures of both reactive and non-reactive gases, and these cylinders come in various sizes to accommodate different needs. Some of the most common cylinder sizes include:

✓ 2AL: 34 liters, pressure at 35.5 bar

✓ 10ALU: 116 liters, pressure at 69 bar

✓ 5AL: 750 liters, pressure at 150 bar

✓ 10AL: 1500 liters, pressure at 69 bar

✓ 10ST: 1500 liters, pressure at 150 bar

These cylinder sizes cater to different calibration requirements, ensuring that you have the right amount of span gas for your specific applications.

Regulators are devices used to control the flow of gases from a pressurized gas cylinder to the instrument being calibrated. In the context of gas detectors, regulators are used to ensure that a consistent flow of span gas is delivered to the detector during the calibration process. This helps maintain a stable and controlled environment for calibration. Regulators typically have pressure gauges and controls to adjust the flow rate of gas to match the requirements of the calibration procedure.

Here at Uniservice Unisafe, our span gas solutions and regulators work together to elevate safety and security in maritime operations. We take pride in delivering superior products that are tailored to address the unique challenges of the maritime industry. By setting high standards for gas detector performance at sea, we aim to be your trusted partner, providing top-notch gas detection and calibration solutions that prioritize quality and precision.

Read more about Gas Mixtures Components

Portable gas detectors play a vital role in ensuring safety and preventing potential hazards in the maritime industry. These devices are designed to be carried by individuals, enabling them to quickly identify and respond to the presence of hazardous gases in various maritime settings. Here's how portable gas detectors are applied in the maritime sector: (read below)

- Emergency Response: In emergency situations such as fires, gas leaks, or accidents, portable gas detectors provide real-time information about the presence of gases, allowing emergency response teams to make informed decisions and take appropriate actions to mitigate risks and protect personnel.

- Drilling Rigs and Offshore Platforms: In offshore drilling and exploration activities, portable gas detectors are used to monitor gas levels on drilling rigs and offshore platforms. They help prevent gas-related accidents and ensure the safety of workers in remote and potentially hazardous environments.

- Marine Surveys and Inspections: Portable gas detectors are also used by marine surveyors and inspectors to assess the condition of vessels, ensuring compliance with safety regulations and identifying any potential gas-related issues that need attention.

- Shipyard Operations: During ship maintenance, construction, and repair operations, portable gas detectors are crucial for detecting gases released from welding, painting, and other processes that can pose health and safety risks to workers.

Overall, portable gas detectors in the maritime industry, including those offered by Uniservice Unisafe, play a crucial role in identifying and mitigating gas-related hazards, enhancing safety protocols, and ensuring the well-being of crew members and the environment. Their ability to provide real-time gas concentration readings empowers maritime professionals, facilitated by Uniservice Unisafe's expertise, to make informed decisions and take prompt actions to prevent accidents and protect lives.

Fixed gas detector systems are integral to maritime safety, providing continuous monitoring and early detection of hazardous gases in various settings on ships, vessels, and offshore installations. Here's how fixed gas detector systems are applied in the maritime industry: (read below)

- LNG and LPG Carriers: Vessels carrying liquefied natural gas (LNG) or liquefied petroleum gas (LPG) require specialized gas detection systems to monitor for leaks and prevent the buildup of explosive or flammable gases. Fixed detectors in these cases play a pivotal role in preventing accidents.

- Ballast Tanks and Bilge Areas: Gas detectors are employed in ballast tanks and bilge areas to monitor for gases that can accumulate due to water ingress or cargo residues. Detecting gas buildup helps prevent corrosion, structural damage, and potential explosions.

- Offshore Platforms and Drilling Rigs: Fixed gas detection systems are crucial for offshore installations, such as oil platforms and drilling rigs. These systems monitor for a wide range of gases, including hydrocarbons and toxic gases, to ensure the safety of workers and prevent environmental incidents.

- Pier Operations: In ports and pier areas, fixed gas detectors are used to monitor cargo loading, unloading, and storage operations for any gas leaks that could pose risks to workers, vessels, or nearby communities.

- Safety Compliance: Fixed gas detectors are essential for meeting safety regulations and standards set by maritime authorities and international organizations. Regular monitoring and prompt response to gas alarms are essential components of maritime safety protocols.

In summary, fixed gas detector systems, including those provided by Uniservice Unisafe, are critical components of maritime safety infrastructure. They offer continuous monitoring and early warning of hazardous gas concentrations in various areas of ships, vessels, and offshore installations. These systems, actively implemented by Uniservice Unisafe, effectively help prevent accidents, protect crew members, maintain vessel integrity, and ensure compliance with safety regulations. As an active player in maritime safety, Uniservice Unisafe's contributions significantly contribute to the overall safety and efficiency of maritime operations.

In the maritime industry, both temperature and pressure calibrators are essential tools for maintaining safety, efficiency, and compliance. Regular calibration activities, often performed by trained technicians or specialized service providers such as Uniservice Unisafe, help prevent accidents, ensure reliable performance of critical systems, and contribute to the overall success of maritime operations. (read below)

Temperature and pressure calibrators play a significant role in the maritime industry, ensuring the accuracy and reliability of instruments and systems used onboard ships and marine facilities. Here's a closer look at temperature and pressure calibration in the maritime sector:

1. Temperature Calibrators:

Purpose: Temperature calibrators are used to verify and adjust temperature measurement instruments on ships, such as thermocouples, resistance temperature detectors (RTDs), and temperature transmitters. Accurate temperature readings are critical for various applications, including engine monitoring, cargo storage, and environmental control systems.

Types: There are different types of temperature calibrators, including dry-well calibrators, liquid bath calibrators, and infrared temperature calibrators. Each type serves specific calibration needs.

Maritime Applications: Temperature calibrators are used to ensure the accuracy of temperature sensors in engine rooms, refrigeration systems, and cargo holds. Properly calibrated instruments help prevent equipment malfunctions, maintain optimal storage conditions for perishable goods, and ensure the safety of crew and passengers.

Regulatory Compliance: Compliance with maritime regulations, such as the International Maritime Organization's (IMO) SOLAS (Safety of Life at Sea) requirements, often mandates the regular calibration of critical temperature instruments on vessels.

2. Pressure Calibrators:

Purpose: Pressure calibrators are used to verify and adjust pressure measurement devices like pressure gauges, transmitters, and relief valves. Maintaining accurate pressure readings is essential for the safe operation of various systems on board ships, including hydraulic systems, ballast tanks, and fuel storage.

Types: Pressure calibrators come in various forms, such as hand-held digital calibrators, deadweight testers, and hydraulic pressure calibrators. The choice depends on the specific calibration requirements.

Maritime Applications: Pressure calibration is vital for ensuring the integrity of pressure vessels, pipelines, and safety relief systems. Accurate pressure measurements help prevent overpressure situations, leaks, and other potentially hazardous incidents.

Safety: Pressure calibrators help in identifying and addressing pressure-related issues before they can lead to equipment failures or safety hazards. Regular calibration contributes to the overall safety of maritime operations.

Compliance: Compliance with maritime regulations, such as those outlined in classification societies' rules (e.g., Lloyd's Register, DNV GL), often requires the calibration of pressure instruments to ensure vessel safety and seaworthiness.

Uniservice Unisafe, as a dedicated supplier, offers a comprehensive range of calibration solutions. We provide Calibration Kits and Calibration Services tailored to the specific needs of the maritime sector. Our commitment to excellence ensures that our calibration services meet the stringent standards of the industry.

The results of our calibration services, performed by our expert technicians, are meticulously documented to ensure compliance with regulatory and quality assurance requirements. With Uniservice Unisafe, you can trust in the accuracy and reliability of your maritime instrumentation.

Ullage Temperature Interface Detectors (UTI) are essential components used in the maritime industry for precise measurements and monitoring of liquid cargo levels and temperatures within storage tanks on ships and marine vessels. These detectors play a crucial role in ensuring the safe and efficient transport and storage of various liquids, such as crude oil, chemicals, and other bulk cargoes. (read below)

Uniservice Unisafe, as an active supplier in the maritime industry, provides Ullage Temperature Interface Detectors (UTI) along with a range of other maritime-related solutions. We understand the critical importance of accurate cargo monitoring and safety in maritime operations.

UTIs are typically equipped with advanced sensors and technology that enable them to perform the following functions:

1. Ullage Measurement: UTIs accurately measure the empty space (ullage) within a storage tank. This information is vital for determining the quantity of liquid cargo present and ensuring that tanks are neither overfilled nor underfilled, which could result in safety hazards or economic losses.

2. Temperature Measurement: UTIs also monitor the temperature of the liquid cargo. Accurate temperature data is essential for cargo custody transfer calculations, especially for cargoes whose volume varies significantly with temperature changes.

3. Interface Detection: UTIs can detect the interface between different liquid layers within a tank, which is crucial when transporting multiple cargoes in the same tank. They ensure the separation of different substances, preventing contamination.

4. Data Recording: Modern UTIs are often equipped with data logging capabilities, allowing for the continuous recording of ullage and temperature data. This recorded information can be used for compliance reporting, cargo quality control, and safety assessments.

5. Safety and Compliance: UTIs contribute to the overall safety of maritime operations by helping to prevent overflows, ensuring cargo integrity, and facilitating compliance with international regulations and standards.

Uniservice Unisafe offers a range of essential solutions for the maritime industry, with a particular focus on UTI (Ullage Temperature Interface Detectors). Our comprehensive maritime services include:

UTI Supply: We provide high-quality UTIs designed to meet the rigorous demands of the maritime sector. These detectors are engineered for reliable, precise, and industry-compliant measurements, ensuring the safe and efficient handling of liquid cargo on ships and marine vessels.

Calibration Services: Our expert technicians provide calibration services specifically tailored to UTIs, maintaining their accuracy and reliability. The results of our calibration services are meticulously documented to adhere to regulatory and quality assurance requirements, enhancing the precision of your UTI measurements.

Repair Services: In the event of UTI malfunction or damage, Uniservice Unisafe offers expert repair services to quickly restore your equipment to optimal working condition. Our dedicated technicians are well-versed in UTI repair, minimizing downtime and ensuring your cargo operations remain efficient.

With Uniservice Unisafe, you can trust in the quality of our UTIs and the expertise of our calibration and repair services. We are committed to providing comprehensive UTI solutions and other maritime services that enhance safety, efficiency, and compliance in maritime operations.

Breath testing in the maritime industry is a crucial safety measure designed to ensure that ship crew members, especially those in safety-sensitive roles like navigating officers, engineers, and operators of heavy machinery, are fit for duty and not under the influence of alcohol or other impairing substances. (read below)

This testing is essential for maintaining the safety of maritime operations, protecting lives, and preventing accidents at sea.

Uniservice Unisafe, a trusted supplier in the maritime industry, provides high-quality breathalyzer devices designed specifically for maritime use. These breathalyzers are essential tools in ensuring compliance with alcohol-related regulations and maintaining safety on board vessels.

Here's an elaboration on breath testing in the maritime industry:

1. Safety and Operational Impact:

- Safety is paramount in the maritime industry. Impaired individuals can pose significant risks to the safety of the crew, the vessel, and the environment.

- Breath testing helps identify individuals who may be unfit for duty due to alcohol consumption or substance use, reducing the potential for accidents, collisions, or operational errors.

2. Regulatory Compliance:

- Many maritime authorities and organizations, such as the International Maritime Organization (IMO), require compliance with strict regulations regarding alcohol and substance use among seafarers.

- Breath testing helps maritime companies and vessels meet these regulatory requirements and maintain their legal and operational standing.

3. Testing Procedures:

- Breath testing typically involves the use of breathalyzer devices that analyze a person's breath to measure blood alcohol concentration (BAC) levels.

- Crew members may be subject to random testing, pre-employment testing, post-incident testing, or testing based on reasonable suspicion.

4. Zero Tolerance Policies:

- Some maritime companies implement zero tolerance policies, meaning any detectable level of alcohol or illegal substances in a crew member's system can result in disciplinary action or dismissal.

- These policies send a strong message about the importance of sobriety and safety within the maritime industry.

5. Education and Awareness:

- Maritime companies often provide education and awareness programs to inform crew members about the risks associated with alcohol and drug use while on duty.

- These programs aim to promote responsible behavior and emphasize the importance of adhering to safety protocols.

6. Random Testing:

- Random breath testing can deter crew members from consuming alcohol or drugs during their off-duty time, as they never know when they may be selected for testing.

- It helps maintain a culture of sobriety and responsibility.

7. Positive Impact on Safety Culture:

- Breath testing can contribute to fostering a safety-conscious culture among maritime professionals, where sobriety and safety go hand in hand.

- It reinforces the idea that everyone on board plays a critical role in ensuring the safety of the vessel and its crew.

In summary, breath testing is a vital component of safety measures in the maritime industry, and Uniservice Unisafe, as a trusted supplier of breathalyzers, plays a crucial role in providing the necessary tools for compliance and safety. It helps ensure that crew members are fit for duty and not impaired by alcohol or substances, contributing to the overall safety and responsibility within the maritime sector.

Authorized Dealer and Service Station

Uniservice Unisafe Gas Detection Systems Check List

Uniservice Unisafe Gas Detection Systems Check List

Uniservice Unisafe ensures a meticulous Gas Detection Systems Check List, encompassing essential steps such as validating detector functionality, precise calibration when needed, and issuance of a fresh compliance certificate. With a focus on swift turnarounds tailored to vessel requirements, we uphold the validity of compliance certification. Our proactive approach involves timely notifications for pending certification and recalibration, ensuring uninterrupted safety. Additionally, we readily provide extra onboard detectors as vessel needs dictate, while our unwavering technical support stands as an ongoing resource for your peace of mind.

- Verify the proper function of a detector.

- Perform any necessary calibration.

- Issue a new certificate of compliance.

- Ensure quick turnaround to suit the vessel’s needs.

- Maintain the validity of compliance certification.

- Notify the device’s owner of pending certification and recalibration of the detector.

- Provide additional onboard detectors as needed by the vessel.

- Offer ongoing technical assistance.