We recognize the critical importance of these elements in ensuring the safety of individuals working in hazardous conditions. Moreover, we emphasize the necessity of prompt equipment servicing. Our global service is designed to connect you directly with our team of safety experts through a well-established network covering major ports worldwide.

UNISAFE, our service division, holds IACS approval as a service supplier for all Classification Registers. We provide top-quality fire protection and safety products, along with comprehensive services on a global scale. Our expertise spans EEBD (Emergency Escape Breathing Device), SCBA (Self-Contained Breathing Apparatus), Chemical Suits, Fireman Suits, Immersion Suits, and Life Jackets.

EEBD SCBA Escape Respirators Immersion Suits Fireman Suits Life Jackets Compressors Chemical Suits

Authorized Dealer and Service Station

What are these?

A Self-Contained Breathing Apparatus (SCBA) is a critical piece of safety equipment used in maritime environments to provide individuals with a supply of clean and breathable air in areas where the ambient air quality is compromised.

SCBAs are essential for ensuring the safety of maritime personnel, especially in situations where they might be exposed to hazardous gases, smoke, or oxygen-deficient atmospheres:

- Emergency Evacuations: In the event of a fire, gas leak, or other emergencies that compromise air quality, SCBAs enable maritime personnel to safely navigate through hazardous conditions and evacuate the vessel.

- Confined Space Entry: Maritime vessels often have confined spaces such as tanks and compartments that can contain toxic or oxygen-deficient atmospheres. SCBAs allow workers to safely enter and perform tasks in these areas.

- Firefighting: SCBAs are essential for firefighting operations on ships. They enable crew members to enter smoke-filled areas and combat fires while maintaining a constant supply of breathable air.

- Search and Rescue: During search and rescue operations at sea, SCBAs ensure that rescuers can navigate through areas with compromised air quality to save lives.

- Environmental Monitoring: SCBAs can also be used in conjunction with gas detectors to assess the air quality in hazardous environments, allowing personnel to take appropriate precautions.

Proper training is crucial for using SCBAs effectively. Maritime personnel must be trained in donning and doffing the equipment, managing air supply, and responding to emergencies. Regular maintenance and inspections are also necessary to ensure the SCBAs are functioning correctly and are ready for immediate use when needed. Active suppliers of SCBAs, such as Uniservice Unisafe, often provide training and maintenance support to ensure that maritime professionals are well-prepared to use this essential equipment in demanding situations.

In essence, SCBAs are indispensable tools in maritime safety, providing individuals with the means to breathe safely in environments where the air quality is compromised. By allowing personnel to operate effectively in hazardous conditions, SCBAs, along with support from active suppliers like Uniservice Unisafe, contribute significantly to the overall safety of maritime operations and the well-being of crew members.

An Emergency Escape Breathing Device (EEBD) is a critical safety apparatus used in maritime environments to provide individuals with a reliable source of breathable air during emergency situations, particularly those involving smoke, toxic gases, or reduced oxygen levels.

EEBDs are designed to facilitate rapid evacuation from hazardous areas and ensure the safety of maritime personnel.

- Emergency Evacuation: In situations such as fires, gas leaks, or toxic fumes, EEBDs enable maritime personnel to swiftly escape hazardous areas while maintaining a supply of breathable air. This is especially important during vessel evacuation procedures.

- Confined Spaces: EEBDs are essential for confined spaces where oxygen levels might be low or toxic gases could accumulate. They allow personnel to exit these spaces safely and efficiently.

- Search and Rescue: During search and rescue operations at sea, EEBDs ensure that rescuers have access to a reliable source of breathable air while navigating through areas with compromised air quality.

Supplier Involvement: Active suppliers of EEBDs, such as Uniservice Unisafe, play a vital role in providing high-quality devices, training, and maintenance support. They ensure that maritime professionals are well-prepared to use EEBDs effectively, enhancing the overall safety of maritime operations and safeguarding the well-being of crew members.

An immersion suit, also known as a survival suit or anti-exposure suit, is a specialized protective garment designed to provide thermal insulation and buoyancy to individuals in cold water environments.

Immersion suits are crucial safety equipment for maritime and offshore industries, especially for personnel working on vessels, oil rigs, or platforms where the risk of falling into cold water is significant. Key features and functions of immersion suits include:

- Thermal Insulation: Immersion suits are constructed with insulating materials that help retain body heat, offering protection against hypothermia in cold water conditions.

- Watertight Sealing: These suits are designed to be watertight, preventing water from entering and ensuring the wearer remains dry.

- Buoyancy: Immersion suits are designed to provide buoyancy, helping the wearer stay afloat and reducing the risk of sinking in water.

- Visibility: Many immersion suits are equipped with reflective tape or bright colors to enhance visibility, making it easier for rescue teams to locate individuals in the water.

- Easy Donning: Immersion suits are engineered for quick and straightforward donning, allowing individuals to put them on rapidly in emergency situations.

- Compliance: Immersion suits often adhere to international safety regulations and standards, ensuring they meet specific requirements for functionality and performance.

- Variety: There are different types of immersion suits available, ranging from one-piece suits to two-piece versions with separate jackets and trousers. These suits are designed to accommodate various body sizes and shapes.

- Storage and Maintenance: Proper storage and regular maintenance are essential to ensure the effectiveness of immersion suits over time. Regular inspections, testing, and maintenance help keep the suits in optimal condition.

Fireman suits, also known as firefighting suits or bunker suits, are specialized protective garments designed to provide maximum protection to firefighters and personnel working in environments with high heat, flames, and potential exposure to hazardous materials.

These suits are essential for individuals who respond to fire emergencies at sea, in ports, or on offshore installations.Key features and functions of fireman suits include:

- Heat Resistance: Fireman suits are made from flame-resistant materials that can withstand high temperatures and protect the wearer from radiant heat and flames.

- Thermal Insulation: These suits provide thermal insulation to shield the wearer from extreme heat, preventing burns and maintaining body temperature.

- Moisture Barrier: Fireman suits often incorporate a moisture barrier that prevents water and other liquids from penetrating the suit, keeping the wearer dry and reducing the risk of steam burns.

- Breathability: Despite their high level of protection, modern fireman suits are designed to allow some degree of breathability to prevent overheating and discomfort during extended use.

- Visibility: Many fireman suits feature reflective stripes or patches to enhance visibility in smoky or low-light conditions, aiding identification and safety.

- Integrated Equipment: Some suits come with integrated harnesses, D-rings, and attachment points for equipment, allowing firefighters to carry essential tools and devices while keeping their hands free.

- Helmet Compatibility: Fireman suits are often designed to accommodate helmets, face shields, and other necessary headgear.

- Durability: Fireman suits are constructed to be durable and resistant to abrasions, tears, and wear and tear that may occur during firefighting operations.

- Regulation Compliance: Fireman suits typically adhere to international standards and regulations for firefighting gear, ensuring their effectiveness and safety in high-risk environments.

- Variety: Different types of fireman suits are available to cater to specific needs, including proximity suits for extreme heat, structural firefighting suits for structural fires, and marine firefighting suits for maritime environments.

Chemical suits, also known as hazmat (hazardous materials) suits or protective chemical clothing, are specialized garments designed to provide full-body protection against hazardous chemicals, liquids, gases, and particles.

These suits are essential for individuals who work with or respond to hazardous substances, such as chemicals, toxins, or radioactive materials, in maritime and industrial settings.Key features and functions of chemical suits include:

- Chemical Resistance: Chemical suits are made from materials that are resistant to a wide range of chemicals, preventing them from permeating through the fabric and coming into contact with the wearer's skin.

- Full-Body Coverage: These suits offer complete coverage, including head, face, body, hands, and feet, minimizing the risk of chemical exposure to any part of the body.

- Sealing and Closures: Chemical suits are designed with sealed seams and closures (such as zippers, flaps, or hook-and-loop fasteners) to ensure a tight and secure fit, preventing chemical entry.

- Breathability: Modern chemical suits are engineered to provide a balance between chemical protection and breathability, allowing wearers to work comfortably for extended periods.

- Visibility: Many chemical suits feature reflective elements or bright colors to enhance visibility, ensuring wearers can be easily identified in hazardous environments.

- Integrated Respiratory Protection: Some chemical suits include integrated or attachable respiratory protection, such as hoods or masks, to safeguard the wearer from inhaling toxic gases or particles.

- Disposable vs. Reusable: Chemical suits come in both disposable and reusable variations, depending on the intended use and level of protection required.

- Regulation Compliance: Chemical suits adhere to stringent safety regulations and standards to ensure they provide the necessary level of protection against hazardous substances.

- Variety: Different types of chemical suits are available to cater to various levels of chemical exposure, including splash suits, encapsulating suits, and level A, B, C, and D suits based on the degree of protection required.

Life jackets, also known as personal flotation devices (PFDs) or life vests, are essential safety equipment designed to keep individuals afloat and provide buoyancy in water.

These jackets are a critical component of maritime safety, intended to prevent drowning and increase the chances of survival for people in emergency situations, such as accidents or vessel evacuations. Key features and functions of life jackets include:

- Buoyancy: The primary function of a life jacket is to provide buoyancy, allowing the wearer to stay afloat in water without expending excess energy.

- Floating Position: Life jackets are designed to keep the wearer's head above water and maintain a face-up floating position, which is crucial for maintaining consciousness and preventing water inhalation.

- Variety: There are different types of life jackets, each designed for specific water environments and activities. These include Type I, Type II, Type III, and Type V life jackets, with varying levels of buoyancy and features.

- Visibility: Many life jackets feature bright colors and reflective elements to enhance visibility, making it easier for rescuers to locate individuals in the water, especially during low light conditions.

- Comfort and Fit: Modern life jackets are designed for comfort and a secure fit. They often have adjustable straps, buckles, and closures to ensure they stay in place during water activities.

- Additional Features: Some life jackets include additional features such as pockets, whistles, lights, and attachment points for safety equipment.

- Regulation Compliance: Life jackets adhere to international safety regulations and standards to ensure their effectiveness in water rescue situations.

- Maintenance: Regular inspection and maintenance are essential to ensure the integrity and functionality of life jackets. Proper storage and care contribute to their longevity.

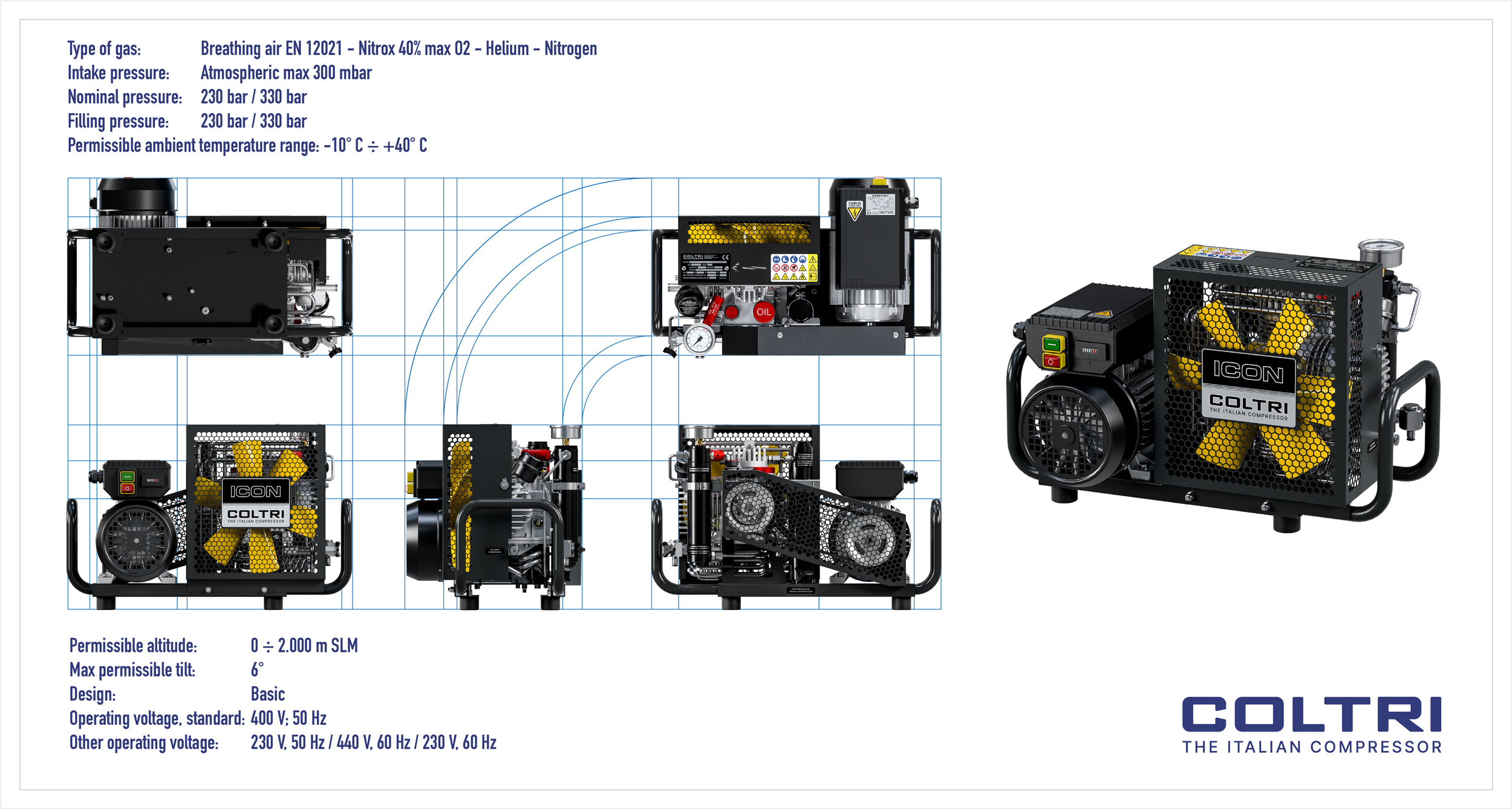

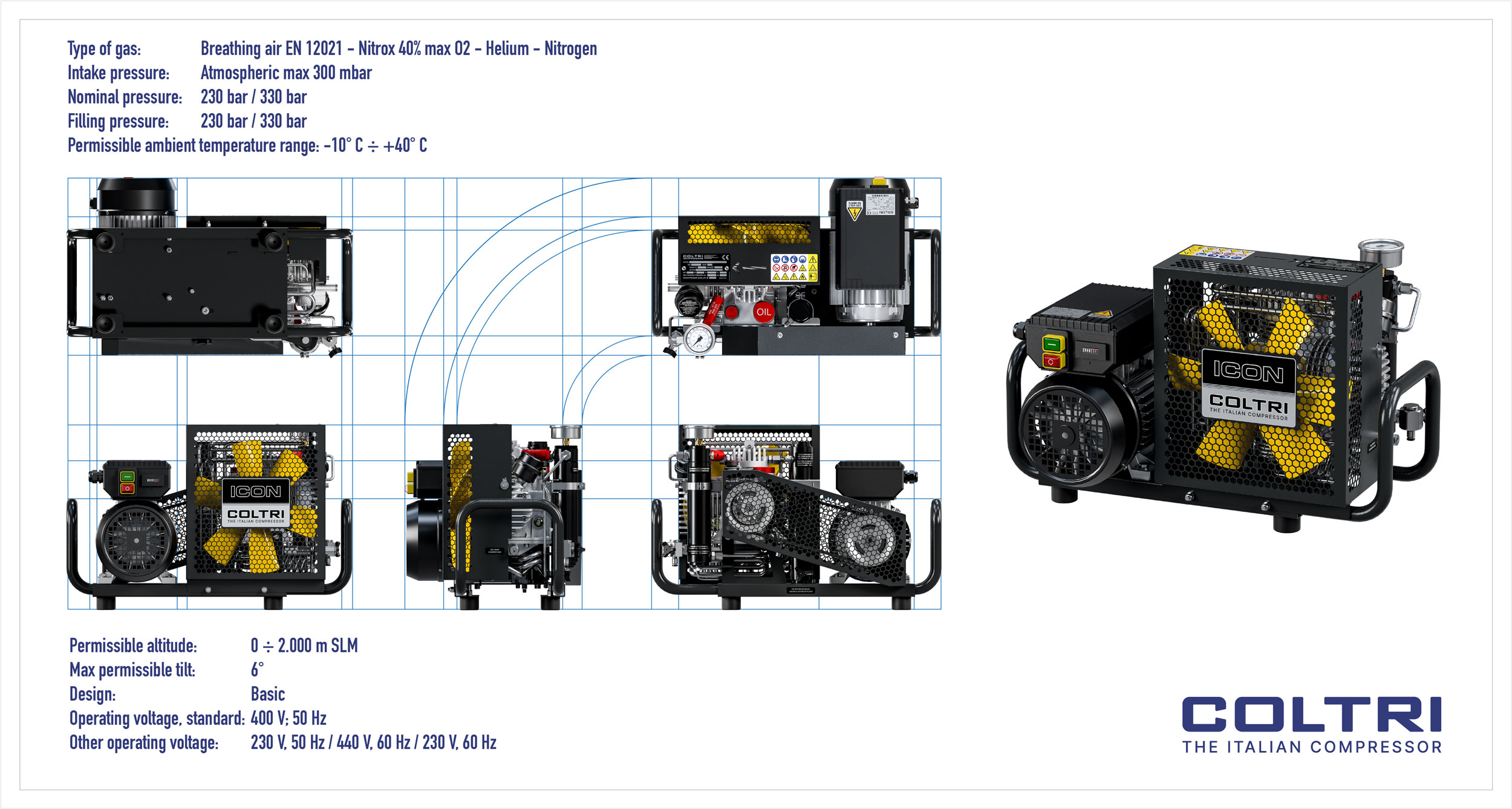

Uniservice Unisafe is a distinguished supplier, specializing in providing top-quality compressors from the best brands for maritime applications. Their reputation in the maritime industry is synonymous with excellence and reliability. (read below)

Portable electric-powered compressors, when employed on board maritime vessels, provide versatility and convenience for a variety of essential tasks. These compact and adaptable devices serve as valuable additions to the vessel's equipment arsenal, offering several key applications:

1. Emergency Repairs: Portable electric compressors are invaluable during emergency situations. They can quickly supply compressed air to power pneumatic tools, allowing crew members to conduct on-the-spot repairs to essential systems and equipment, helping to prevent further damage or downtime.

2. Diving Operations: Maritime vessels engaged in diving operations often require a reliable source of high-pressure air for filling diving cylinders. Portable electric compressors are essential for ensuring that divers have a readily available and safe source of breathing air while on board.

3. Life Raft and Life Jacket Inflation: Safety is paramount on maritime vessels. Portable electric compressors can swiftly inflate life rafts and life jackets in emergency situations, ensuring that these critical safety devices are readily prepared for use.

4. Deck Cleaning and Maintenance: Keeping the vessel's deck clean and well-maintained is essential for the safety of crew members and the longevity of the ship. Portable electric compressors power air-driven cleaning tools, such as air blowers and deck washers, making deck maintenance efficient and effective.

5. Tire Inflation: Some vessels carry vehicles or equipment with pneumatic tires on board. Portable electric compressors can be used to inflate these tires to the appropriate pressure, ensuring the proper functioning and safety of the vehicles and equipment.

6. Painting and Surface Preparation: Painting and surface preparation tasks often require pneumatic spray guns and sandblasters. Portable electric compressors provide the necessary compressed air for these applications, facilitating painting and surface finishing processes.

7. Instrument Calibration: Precision instruments on board maritime vessels, such as pressure gauges and sensors, may require periodic calibration. Portable electric compressors can be used to generate precise and consistent air pressure for calibration purposes, ensuring the accuracy of these critical instruments.

8. Emergency Air Supply: In situations where the vessel's primary compressed air system is compromised, a portable electric compressor can serve as a backup air supply source. This redundancy enhances safety by ensuring that crew members have access to essential services, such as emergency breathing air and firefighting equipment.

9. Utility Work: Portable compressors can support utility work on board, such as providing air for pneumatic tools used in routine maintenance, construction, and repair tasks.

10. Auxiliary Power Source: Some portable electric compressors may have additional electrical outlets or power capabilities, allowing them to serve as auxiliary power sources for various onboard equipment and devices.

Robust Maritime Design: Compressors supplied by Uniservice Unisafe feature rugged casings constructed from marine-grade materials. They are corrosion-resistant and built to withstand the challenges of saltwater exposure, ensuring longevity and durability during extended maritime journeys. Their compact sizes and user-friendly handles enhance their portability, making them practical choices for transportation and onboard storage.

Electric-Powered Efficiency: These compressors operate efficiently on electricity, harnessing power from the ship's electrical system or onboard generators. They consistently deliver reliable compressed air output, catering to a diverse range of maritime applications.

Exceptional Performance: The compressors, chosen by Uniservice Unisafe, excel in performance. They possess the capability to deliver a high volume of compressed air at varying pressures, making them versatile solutions for powering pneumatic tools, filling diving cylinders, inflating life rafts, and supporting essential onboard systems.

Safety First: Uniservice Unisafe places safety at the forefront. The compressors come equipped with a comprehensive array of safety features, including pressure relief valves, temperature sensors, and automatic shutdown mechanisms. These safety measures are designed to prevent overheating and overpressure situations, ensuring the well-being of your crew. The compressors adhere to stringent international safety standards, providing peace of mind.

User-Friendly Interface: Operating the compressors is a straightforward task, thanks to their intuitive control panels. Operators can effortlessly set desired pressure levels and monitor performance metrics, facilitating precise and secure operation.

Environmental Responsibility: Uniservice Unisafe is committed to environmental sustainability. The selected compressors, sourced from top brands, incorporate features to minimize emissions and noise pollution. They include elements such as low-noise operation and eco-friendly refrigerants, aligning with environmental regulations and reducing their ecological impact.

Reliability and Service: Uniservice Unisafe places utmost importance on reliability. They ensure that you receive compressors backed by expert support, guaranteeing that your maritime operations run smoothly and efficiently.

Choose Uniservice Unisafe as your trusted supplier for a variety of top compressor brands and expert compressor services in the maritime industry. Experience the peace of mind that comes with superior quality and Uniservice Unisafe's unwavering commitment to meeting your maritime needs.

What are these?

A Self-Contained Breathing Apparatus (SCBA) is a critical piece of safety equipment used in maritime environments to provide individuals with a supply of clean and breathable air in areas where the ambient air quality is compromised.

SCBAs are essential for ensuring the safety of maritime personnel, especially in situations where they might be exposed to hazardous gases, smoke, or oxygen-deficient atmospheres:

- Emergency Evacuations: In the event of a fire, gas leak, or other emergencies that compromise air quality, SCBAs enable maritime personnel to safely navigate through hazardous conditions and evacuate the vessel.

- Confined Space Entry: Maritime vessels often have confined spaces such as tanks and compartments that can contain toxic or oxygen-deficient atmospheres. SCBAs allow workers to safely enter and perform tasks in these areas.

- Firefighting: SCBAs are essential for firefighting operations on ships. They enable crew members to enter smoke-filled areas and combat fires while maintaining a constant supply of breathable air.

- Search and Rescue: During search and rescue operations at sea, SCBAs ensure that rescuers can navigate through areas with compromised air quality to save lives.

- Environmental Monitoring: SCBAs can also be used in conjunction with gas detectors to assess the air quality in hazardous environments, allowing personnel to take appropriate precautions.

Proper training is crucial for using SCBAs effectively. Maritime personnel must be trained in donning and doffing the equipment, managing air supply, and responding to emergencies. Regular maintenance and inspections are also necessary to ensure the SCBAs are functioning correctly and are ready for immediate use when needed. Active suppliers of SCBAs, such as Uniservice Unisafe, often provide training and maintenance support to ensure that maritime professionals are well-prepared to use this essential equipment in demanding situations.

In essence, SCBAs are indispensable tools in maritime safety, providing individuals with the means to breathe safely in environments where the air quality is compromised. By allowing personnel to operate effectively in hazardous conditions, SCBAs, along with support from active suppliers like Uniservice Unisafe, contribute significantly to the overall safety of maritime operations and the well-being of crew members.

An Emergency Escape Breathing Device (EEBD) is a critical safety apparatus used in maritime environments to provide individuals with a reliable source of breathable air during emergency situations, particularly those involving smoke, toxic gases, or reduced oxygen levels.

EEBDs are designed to facilitate rapid evacuation from hazardous areas and ensure the safety of maritime personnel.

- Emergency Evacuation: In situations such as fires, gas leaks, or toxic fumes, EEBDs enable maritime personnel to swiftly escape hazardous areas while maintaining a supply of breathable air. This is especially important during vessel evacuation procedures.

- Confined Spaces: EEBDs are essential for confined spaces where oxygen levels might be low or toxic gases could accumulate. They allow personnel to exit these spaces safely and efficiently.

- Search and Rescue: During search and rescue operations at sea, EEBDs ensure that rescuers have access to a reliable source of breathable air while navigating through areas with compromised air quality.

Supplier Involvement: Active suppliers of EEBDs, such as Uniservice Unisafe, play a vital role in providing high-quality devices, training, and maintenance support. They ensure that maritime professionals are well-prepared to use EEBDs effectively, enhancing the overall safety of maritime operations and safeguarding the well-being of crew members.

An immersion suit, also known as a survival suit or anti-exposure suit, is a specialized protective garment designed to provide thermal insulation and buoyancy to individuals in cold water environments.

Immersion suits are crucial safety equipment for maritime and offshore industries, especially for personnel working on vessels, oil rigs, or platforms where the risk of falling into cold water is significant. Key features and functions of immersion suits include:

- Thermal Insulation: Immersion suits are constructed with insulating materials that help retain body heat, offering protection against hypothermia in cold water conditions.

- Watertight Sealing: These suits are designed to be watertight, preventing water from entering and ensuring the wearer remains dry.

- Buoyancy: Immersion suits are designed to provide buoyancy, helping the wearer stay afloat and reducing the risk of sinking in water.

- Visibility: Many immersion suits are equipped with reflective tape or bright colors to enhance visibility, making it easier for rescue teams to locate individuals in the water.

- Easy Donning: Immersion suits are engineered for quick and straightforward donning, allowing individuals to put them on rapidly in emergency situations.

- Compliance: Immersion suits often adhere to international safety regulations and standards, ensuring they meet specific requirements for functionality and performance.

- Variety: There are different types of immersion suits available, ranging from one-piece suits to two-piece versions with separate jackets and trousers. These suits are designed to accommodate various body sizes and shapes.

- Storage and Maintenance: Proper storage and regular maintenance are essential to ensure the effectiveness of immersion suits over time. Regular inspections, testing, and maintenance help keep the suits in optimal condition.

Fireman suits, also known as firefighting suits or bunker suits, are specialized protective garments designed to provide maximum protection to firefighters and personnel working in environments with high heat, flames, and potential exposure to hazardous materials.

These suits are essential for individuals who respond to fire emergencies at sea, in ports, or on offshore installations.Key features and functions of fireman suits include:

- Heat Resistance: Fireman suits are made from flame-resistant materials that can withstand high temperatures and protect the wearer from radiant heat and flames.

- Thermal Insulation: These suits provide thermal insulation to shield the wearer from extreme heat, preventing burns and maintaining body temperature.

- Moisture Barrier: Fireman suits often incorporate a moisture barrier that prevents water and other liquids from penetrating the suit, keeping the wearer dry and reducing the risk of steam burns.

- Breathability: Despite their high level of protection, modern fireman suits are designed to allow some degree of breathability to prevent overheating and discomfort during extended use.

- Visibility: Many fireman suits feature reflective stripes or patches to enhance visibility in smoky or low-light conditions, aiding identification and safety.

- Integrated Equipment: Some suits come with integrated harnesses, D-rings, and attachment points for equipment, allowing firefighters to carry essential tools and devices while keeping their hands free.

- Helmet Compatibility: Fireman suits are often designed to accommodate helmets, face shields, and other necessary headgear.

- Durability: Fireman suits are constructed to be durable and resistant to abrasions, tears, and wear and tear that may occur during firefighting operations.

- Regulation Compliance: Fireman suits typically adhere to international standards and regulations for firefighting gear, ensuring their effectiveness and safety in high-risk environments.

- Variety: Different types of fireman suits are available to cater to specific needs, including proximity suits for extreme heat, structural firefighting suits for structural fires, and marine firefighting suits for maritime environments.

Chemical suits, also known as hazmat (hazardous materials) suits or protective chemical clothing, are specialized garments designed to provide full-body protection against hazardous chemicals, liquids, gases, and particles.

These suits are essential for individuals who work with or respond to hazardous substances, such as chemicals, toxins, or radioactive materials, in maritime and industrial settings.Key features and functions of chemical suits include:

- Chemical Resistance: Chemical suits are made from materials that are resistant to a wide range of chemicals, preventing them from permeating through the fabric and coming into contact with the wearer's skin.

- Full-Body Coverage: These suits offer complete coverage, including head, face, body, hands, and feet, minimizing the risk of chemical exposure to any part of the body.

- Sealing and Closures: Chemical suits are designed with sealed seams and closures (such as zippers, flaps, or hook-and-loop fasteners) to ensure a tight and secure fit, preventing chemical entry.

- Breathability: Modern chemical suits are engineered to provide a balance between chemical protection and breathability, allowing wearers to work comfortably for extended periods.

- Visibility: Many chemical suits feature reflective elements or bright colors to enhance visibility, ensuring wearers can be easily identified in hazardous environments.

- Integrated Respiratory Protection: Some chemical suits include integrated or attachable respiratory protection, such as hoods or masks, to safeguard the wearer from inhaling toxic gases or particles.

- Disposable vs. Reusable: Chemical suits come in both disposable and reusable variations, depending on the intended use and level of protection required.

- Regulation Compliance: Chemical suits adhere to stringent safety regulations and standards to ensure they provide the necessary level of protection against hazardous substances.

- Variety: Different types of chemical suits are available to cater to various levels of chemical exposure, including splash suits, encapsulating suits, and level A, B, C, and D suits based on the degree of protection required.

Life jackets, also known as personal flotation devices (PFDs) or life vests, are essential safety equipment designed to keep individuals afloat and provide buoyancy in water.

These jackets are a critical component of maritime safety, intended to prevent drowning and increase the chances of survival for people in emergency situations, such as accidents or vessel evacuations. Key features and functions of life jackets include:

- Buoyancy: The primary function of a life jacket is to provide buoyancy, allowing the wearer to stay afloat in water without expending excess energy.

- Floating Position: Life jackets are designed to keep the wearer's head above water and maintain a face-up floating position, which is crucial for maintaining consciousness and preventing water inhalation.

- Variety: There are different types of life jackets, each designed for specific water environments and activities. These include Type I, Type II, Type III, and Type V life jackets, with varying levels of buoyancy and features.

- Visibility: Many life jackets feature bright colors and reflective elements to enhance visibility, making it easier for rescuers to locate individuals in the water, especially during low light conditions.

- Comfort and Fit: Modern life jackets are designed for comfort and a secure fit. They often have adjustable straps, buckles, and closures to ensure they stay in place during water activities.

- Additional Features: Some life jackets include additional features such as pockets, whistles, lights, and attachment points for safety equipment.

- Regulation Compliance: Life jackets adhere to international safety regulations and standards to ensure their effectiveness in water rescue situations.

- Maintenance: Regular inspection and maintenance are essential to ensure the integrity and functionality of life jackets. Proper storage and care contribute to their longevity.

Uniservice Unisafe is a distinguished supplier, specializing in providing top-quality compressors from the best brands for maritime applications. Their reputation in the maritime industry is synonymous with excellence and reliability. (read below)

Portable electric-powered compressors, when employed on board maritime vessels, provide versatility and convenience for a variety of essential tasks. These compact and adaptable devices serve as valuable additions to the vessel's equipment arsenal, offering several key applications:

1. Emergency Repairs: Portable electric compressors are invaluable during emergency situations. They can quickly supply compressed air to power pneumatic tools, allowing crew members to conduct on-the-spot repairs to essential systems and equipment, helping to prevent further damage or downtime.

2. Diving Operations: Maritime vessels engaged in diving operations often require a reliable source of high-pressure air for filling diving cylinders. Portable electric compressors are essential for ensuring that divers have a readily available and safe source of breathing air while on board.

3. Life Raft and Life Jacket Inflation: Safety is paramount on maritime vessels. Portable electric compressors can swiftly inflate life rafts and life jackets in emergency situations, ensuring that these critical safety devices are readily prepared for use.

4. Deck Cleaning and Maintenance: Keeping the vessel's deck clean and well-maintained is essential for the safety of crew members and the longevity of the ship. Portable electric compressors power air-driven cleaning tools, such as air blowers and deck washers, making deck maintenance efficient and effective.

5. Tire Inflation: Some vessels carry vehicles or equipment with pneumatic tires on board. Portable electric compressors can be used to inflate these tires to the appropriate pressure, ensuring the proper functioning and safety of the vehicles and equipment.

6. Painting and Surface Preparation: Painting and surface preparation tasks often require pneumatic spray guns and sandblasters. Portable electric compressors provide the necessary compressed air for these applications, facilitating painting and surface finishing processes.

7. Instrument Calibration: Precision instruments on board maritime vessels, such as pressure gauges and sensors, may require periodic calibration. Portable electric compressors can be used to generate precise and consistent air pressure for calibration purposes, ensuring the accuracy of these critical instruments.

8. Emergency Air Supply: In situations where the vessel's primary compressed air system is compromised, a portable electric compressor can serve as a backup air supply source. This redundancy enhances safety by ensuring that crew members have access to essential services, such as emergency breathing air and firefighting equipment.

9. Utility Work: Portable compressors can support utility work on board, such as providing air for pneumatic tools used in routine maintenance, construction, and repair tasks.

10. Auxiliary Power Source: Some portable electric compressors may have additional electrical outlets or power capabilities, allowing them to serve as auxiliary power sources for various onboard equipment and devices.

Robust Maritime Design: Compressors supplied by Uniservice Unisafe feature rugged casings constructed from marine-grade materials. They are corrosion-resistant and built to withstand the challenges of saltwater exposure, ensuring longevity and durability during extended maritime journeys. Their compact sizes and user-friendly handles enhance their portability, making them practical choices for transportation and onboard storage.

Electric-Powered Efficiency: These compressors operate efficiently on electricity, harnessing power from the ship's electrical system or onboard generators. They consistently deliver reliable compressed air output, catering to a diverse range of maritime applications.

Exceptional Performance: The compressors, chosen by Uniservice Unisafe, excel in performance. They possess the capability to deliver a high volume of compressed air at varying pressures, making them versatile solutions for powering pneumatic tools, filling diving cylinders, inflating life rafts, and supporting essential onboard systems.

Safety First: Uniservice Unisafe places safety at the forefront. The compressors come equipped with a comprehensive array of safety features, including pressure relief valves, temperature sensors, and automatic shutdown mechanisms. These safety measures are designed to prevent overheating and overpressure situations, ensuring the well-being of your crew. The compressors adhere to stringent international safety standards, providing peace of mind.

User-Friendly Interface: Operating the compressors is a straightforward task, thanks to their intuitive control panels. Operators can effortlessly set desired pressure levels and monitor performance metrics, facilitating precise and secure operation.

Environmental Responsibility: Uniservice Unisafe is committed to environmental sustainability. The selected compressors, sourced from top brands, incorporate features to minimize emissions and noise pollution. They include elements such as low-noise operation and eco-friendly refrigerants, aligning with environmental regulations and reducing their ecological impact.

Reliability and Service: Uniservice Unisafe places utmost importance on reliability. They ensure that you receive compressors backed by expert support, guaranteeing that your maritime operations run smoothly and efficiently.

Choose Uniservice Unisafe as your trusted supplier for a variety of top compressor brands and expert compressor services in the maritime industry. Experience the peace of mind that comes with superior quality and Uniservice Unisafe's unwavering commitment to meeting your maritime needs.